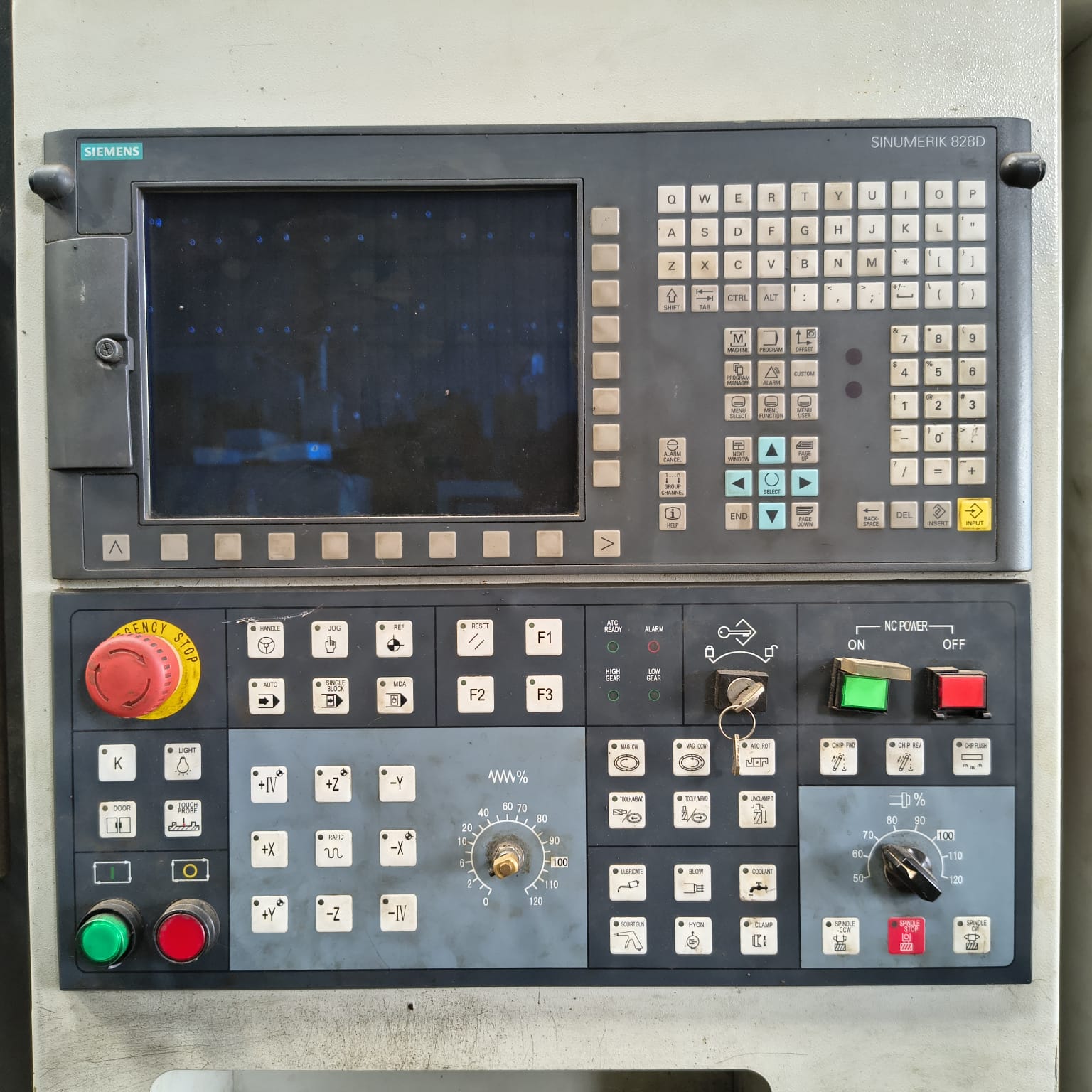

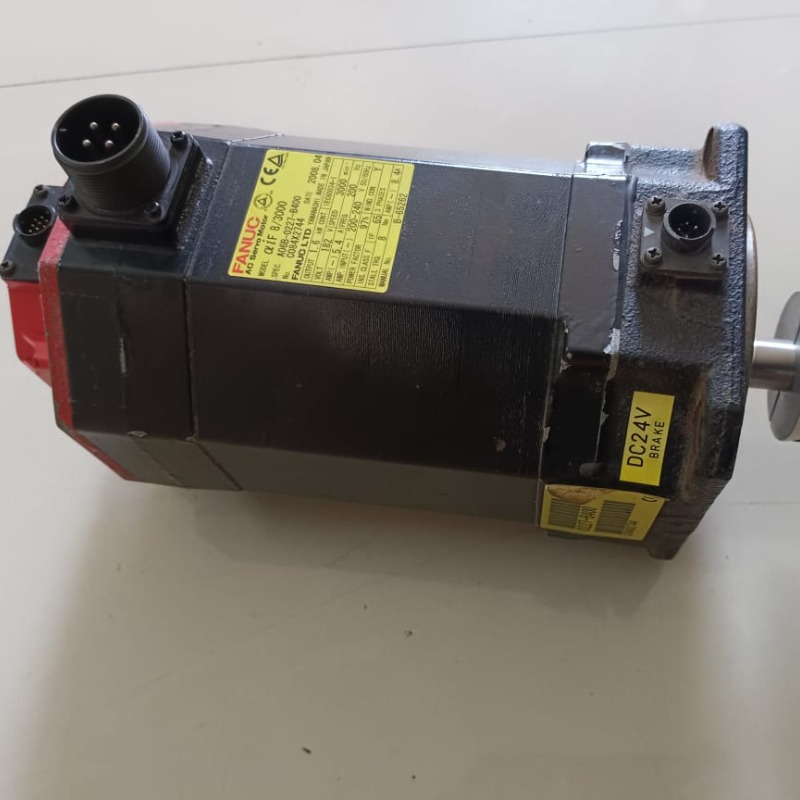

This CNC machining center features a robust 3-axis configuration with a maximum travel of X: 33.46 inches, Y: 22.05 inches, and Z: 25.59 inches, providing ample workspace for a wide range of milling applications. The machine is equipped with a FANUC CNC control system, renowned for its reliability, precision, and user-friendly interface, supporting advanced programming and seamless integration into automated manufacturing environments. The table measures 19.69 inches in width and 39.37 inches in length, offering a stable and versatile platform for securely holding workpieces of various sizes. Powered by a 20.1 hp spindle motor, the machine delivers high torque and consistent performance for demanding cutting tasks, ensuring efficient material removal and excellent surface finishes. The FANUC control enables precise axis positioning, rapid tool changes, and smooth operation, while built-in safety features and diagnostic tools enhance machine uptime and operator confidence. Ideal for general milling, prototyping, and production environments, this CNC machining center combines proven FANUC technology with a compact footprint and high productivity, making it a reliable choice for shops seeking accuracy, durability, and ease of use.

No Review Found.

Related Products

Sign up to newslatter

COPYRIGHT © 2025. All Rights Reserved By TNCNC

Login To Comment